How many components went obsolete without a PCN in 2023?

In our recent poll conducted on LinkedIn, we asked the FOM community to test their knowledge on how many components went obsolete without a PCN in 2023. Without proper notification through a Product Change Notification (PCN), the sudden obsolescence of components can lead to significant disruptions and challenges for companies.

Poll Results

The poll results provide valuable insights into the prevalence of components going obsolete without a PCN in 2023. Here’s a breakdown of the responses:

Source: Converge FOM Showcase LinkedIn Poll

When looking at these results, there is a varied opinion on the number of components that went obsolete without a PCN. Even with notifications of parts going end-of-life, obsolescence management remains a real problem. When there is no notice, or the opportunity to purchase Last-Time-Buys (LTB) is limited, the issues are magnified.

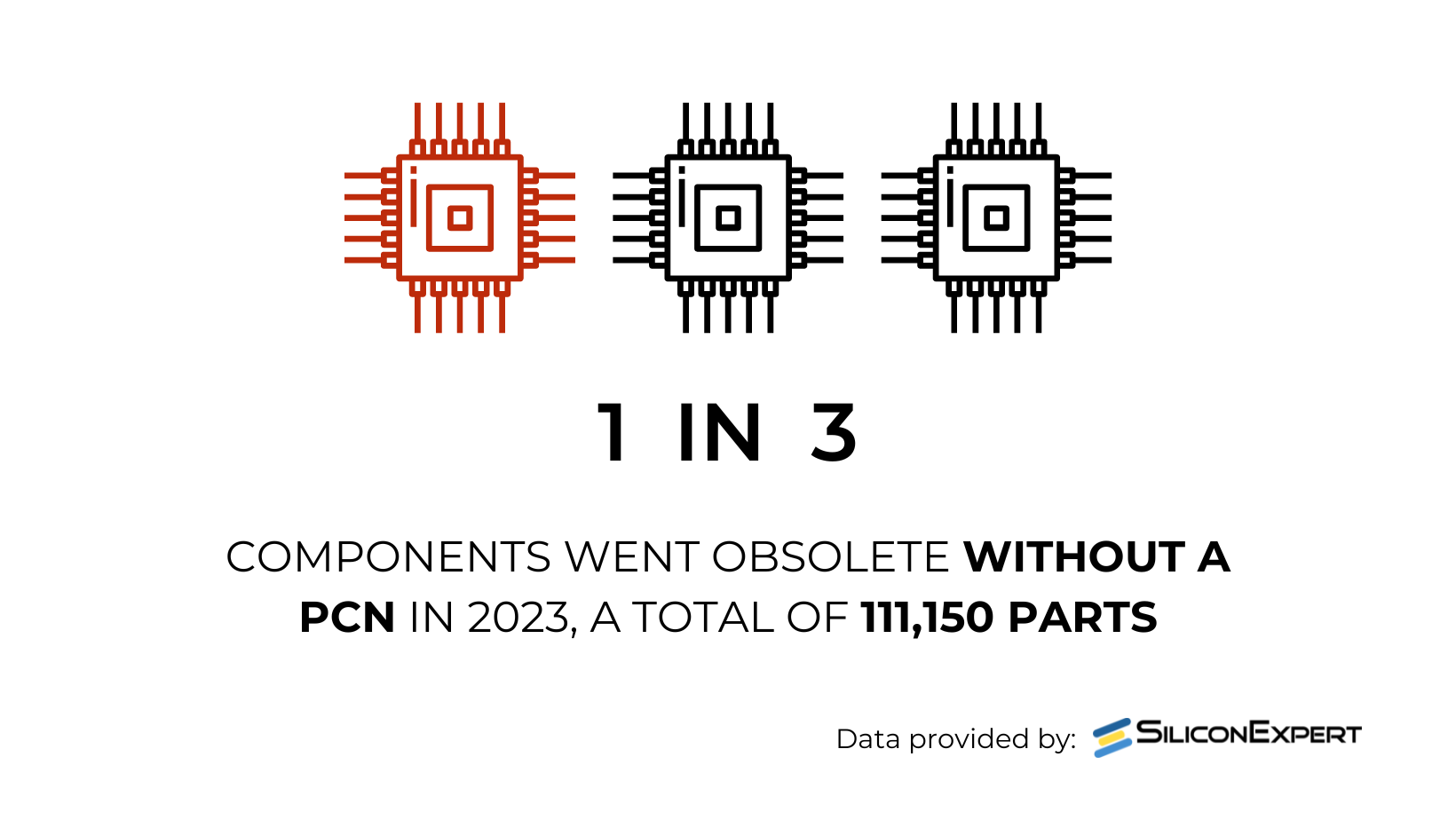

The correct answer is between 100,000 to 150,000, with a total of 111,150 parts going obsolete without a PCN in 2023.

Proof in the Data

Our sister company, SiliconExpert, which maintains the world’s most comprehensive database on electronic components including obsolescence, PCNs, and LTBs information, provided the total number of parts that went obsolete in 2023.

111,150 components went obsolete without a PCN in 2023, in other words, 1 out of 3 parts — a significant number that simply did not have a notification.

What Can You Do

Managing obsolescence within your supply chain isn’t easy and then when there are no notifications sent on these changes, it can blindside even the most robust obsolescence strategies. There are a few things you can do to help combat these unexpected events:

Strengthen Collaboration with Suppliers: Establishing strong relationships with suppliers can enhance communication and increase the likelihood of early obsolescence notifications.

Implement Obsolescence Management & Data Systems: Deploying comprehensive obsolescence management tools, like SiliconExpert, and processes can help monitor component lifecycle statuses, identify potential risks, and enable proactive decision-making to mitigate obsolescence challenges.

Diversify Component Sources: Relying on a single supplier for critical components increases vulnerability to obsolescence. Working with a trusted supply chain partner, like Converge, can reduce the risks associated with obsolescence. Ensure they are reputable and have a fortified quality management program to prevent any counterfeit or substandard parts from entering your supply chain.

Join the FOM Community: The Future of Obsolescence Management Community is an international network of individuals and organizations that deal with the challenges of obsolescence and have a common goal of tackling these growing demands through collaboration and sharing ideas.

These statistics are only the tip of the iceberg of the challenges of managing obsolescence. They highlight the importance of not only proactive strategies but also reactive strategies after EOL events happen. By strengthening supplier relationships, using a comprehensive component database, partnering with a trusted supply chain partner like Converge, and joining the FOM Community you can keep product lines running and generating revenue for your business.

Let Converge find your obsolete and hard-to-find parts.

Disclaimer: The results of this poll are based on opinions expressed by participants and may not fully represent the overall industry trends or future developments.

Stay connected and subscribe!